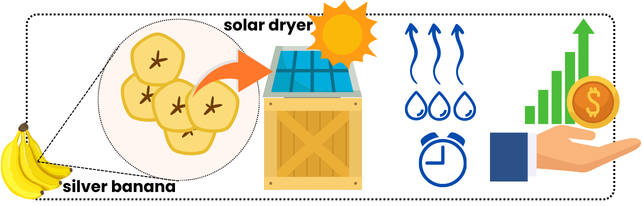

Low-cost solar dryer dehydrates silver banana with a prediction of diffusion approximation model

DOI:

https://doi.org/10.58951/fstoday.2024.008Keywords:

diffusion coefficient, fruit drying, Musa spp., prediction models, solar dryingAbstract

Solar dryers made from recycled materials offer a cost-effective solution for promoting the widespread adoption of this technology and reducing food production costs. In this study, a low-cost solar dryer was constructed using repurposed materials, employing indirect exposure, and its performance was evaluated through a kinetic study on banana slice drying (Musa spp.). Drying was carried out until equilibrium moisture, reaching constant mass. The drying air's temperature and relative humidity (RH, %) were monitored. Fourteen empirical models were used to fit the experimental data. The banana slices took approximately 300 min to dry, with final moisture of 1.8%. The mean operational conditions during natural drying were 59.08±9.16 °C and RH = 39±4%. The diffusion Approximation model fitted the drying curve better, as it presented the lowest reduced Chi-square (χ2 = 2.9×10-5) and a high coefficient of determination (R2 = 0.9998). The effective diffusion coefficient (Def = 5.4×10-9 m2/s, R2 = 0.9935) was determined. Thus, the solar dryer demonstrated efficient performance in the banana drying process, requiring minimal design effort. Furthermore, despite the limitations in controlling the drying conditions, most of the mathematical models successfully predicted the drying process due to the dryer's ability to maintain the continuity of the drying curve, suggesting potential viability for this low-cost dryer.

References

Almeida, R. F. (2024). Solar drying data for banana slices [Data set]. Zenodo. https://doi.org/https://doi.org/10.5281/zenodo.12819829

Almeida, R. F., Bevilaqua, G. C., & Machado, A. P. O. (2022). Design, construction, and application of a low‐cost solar dryer: A kinetic study of Araticum pulp drying. Journal of Food Processing and Preservation, 46(12). https://doi.org/10.1111/jfpp.17200

Almeida, R. F., Gomes, M. H. G., & Kurozawa, L. E. (2023). Rice bran protein increases the retention of anthocyanins by acting as an encapsulating agent in the spray drying of grape juice. Food Research International, 172, 113237. https://doi.org/10.1016/j.foodres.2023.113237

Almeida, R. F., Gomes, M. H. G., & Kurozawa, L. E. (2024). Enzymatic hydrolysis improves the encapsulation properties of rice bran protein by increasing retention of anthocyanins in microparticles of grape juice. Food Research International, 180, 114090. https://doi.org/10.1016/j.foodres.2024.114090

Almeida, R. F., Moreno, I. F., Machado, A. P. O., Meireles, M. A. A., da Silva, L. K. F., & Batista, E. A. C. (2024). Araticum (Annona crassiflora Mart.): A critical review for the food industry. Food Research International, 114241. https://doi.org/10.1016/j.foodres.2024.114241

Association of Official Analytical Chemists - AOAC. (2019). Official Methods of Analysis of the AOAC International: Three-Volume set. 21st. ed., AOAC, Maryland: AOAC International. v.1-3. 2019. 3390f.

Baini, R., & Langrish, T. A. G. (2007). Choosing an appropriate drying model for intermittent and continuous drying of bananas. Journal of Food Engineering, 79(1), 330–343. https://doi.org/10.1016/j.jfoodeng.2006.01.068

Belghith, A., Azzouz, S., & ElCafsi, A. (2016). Desorption isotherms and mathematical modeling of thin layer drying kinetics of tomato. Heat and Mass Transfer, 52(3), 407–419. https://doi.org/10.1007/s00231-015-1560-0

Bezerra, F. D., & Santos, L. S. dos. (2016). Energia solar no Nordeste. Caderno Setorial ETENE, 1(1), 26–40.

Borges, S. V., Mancini, M. C., Corrêa, J. L. G., & Leite, J. (2010). Secagem de bananas prata e d’água por convecção forçada. Ciência e Tecnologia de Alimentos, 30(3), 605–612. https://doi.org/10.1590/S0101-20612010000300006

Brazilian Food Composition Table (TBCA). University of São Paulo (USP). Food Research Center (FoRC). Version 7.2. São Paulo, 2022. Access at: 10 August 2024. Available at: <http://www.fcf.usp.br/tbca>

BSW-Solar (2013). Statistic data on the German solar power (photovoltaic) industry. German Solar Industry Association (BSW-Solar). Available at:

Caballero, B., Finglas, P., & Toldrá, F. (2016). Encyclopedia of food and health. Academic Press. vol. 4, 1st edition. Oxford: Acadermic Press, Elsevier Ltd.

Camelo, R. S. da S., Paes, J. L., Braz, M. R. S., Bruggianesi, G., & Guimarães, C. L. (2019). Kinetics drying of silver banana (Musa spp.) in hybrid dryer. Revista Ciencia Agronomica, 50(3), 353–360. https://doi.org/10.5935/1806-6690.20190042

Carvalho, C. de, Kist, B. B., & Beling, R. R. (2019). Anuário Brasileiro de Horti & Fruti 2022 [Brazilian Horti & Fruti Yearbook 2020]. Editora Gazeta Santa Cruz.

Celestino, S. M. C. (2010). Princípios de Secagem de Alimentos. Embrapa Cerrado. 51p.

Centro Paranaense de Referência em Agroecologia - CPRA. (2009). Secagem/Desidratação – Plantas Medicinais Aromáticas e Condimentares, Frutas e Hortaliças. CPRA.

Climate-Data.Org. (2021). Barreiras clima (Brasil). Climate-Data.Org. Available at: <https://pt.climate-data.org/america-do-sul/brasil/bahia/barreiras-4464/>

Costa, Z. R. T., Silva, L. P. F. R., Alves, V. R., Silva, H. A., & Vieira, A. F. (2018). Modelos matemáticos da cinética de secagem de banana (Musa ssp.). In Congresso Técnico Científico da Engenharia e da Agronomia - CONTECC’2018. Anais de Conferências (5 p.). CONTECC.

Deamici, K. M., Oliveira, L. C. de, Rosa, G. S. da, & Oliveira, E. G. de. (2016). Drying kinetics of fermented grape pomace: Determination of moisture effective diffusivity. Revista Brasileira de Engenharia Agrícola e Ambiental, 20(8), 763–768. https://doi.org/10.1590/1807-1929/agriambi.v20n8p763-768

Elangovan, E., & Natarajan, S. K. (2021). Experimental Research of Drying Characteristics of Red Banana in a Single Slope Direct Solar Dryer Based on Natural and Forced Convection. Food Technology and Biotechnology, 59(2), 137–146. https://doi.org/10.17113/ftb.59.02.21.6876

Etim, P. J., Eke, A. Ben, & Simonyan, K. J. (2020). Design and development of an active indirect solar dryer for cooking banana. Scientific African, 8, e00463. https://doi.org/10.1016/j.sciaf.2020.e00463

FAO. (2019). Uma vez esquecidas, estas culturas tradicionais são a nossa nova esperança. Food and Agriculture Organization. Available at: <https://www.fao.org/brasil/noticias/detail-events/pt/c/1195175/>

FAO. (2021). Food losses and waste in Latin America and the Caribbean. Food and Agriculture Organization. Food and Agriculture Organization. Available at: <http://www.fao.org/americas/noticias/ver/pt/c/239394/>

FAO. (2023). FAOSTAT - Crops and livestock products. Food and Agriculture Organization of United Nations. Available at: <https://www.fao.org/faostat/en/#data/QCL>

Farias, R. P. de, Silva, W. P., Magalhães, H. L. F., Lima, W. M. P. B. de, Gomez, R. S., Lima, E. S. de, Silva, S. K. B. M. da, & Lima, A. G. B. de. (2020). Estudo teórico e experimental da secagem de banana inteira em estufa. Research, Society and Development, 9(11), e56991110093. https://doi.org/10.33448/rsd-v9i11.10093

Food Ingredients Brasil. (2016). A desidratação na conservação dos alimentos. Revista FI, 38, 68–75.

Geankopolis, C. J. (1998). Procesos de transporte y operaciones unitárias (3rd ed.). Compañía Editorial Continental (CECSA). 1008 p.

Imperial, L. C. C., & Pereira, O. S. (2014). Análise do potencial do recurso solar na Bahia a partir de software de informação geográfica baseado na web. In: V Congresso Brasileiro de Energia Solar. Recife (Ed.). Anais de Conferências. Associação Brasileira de Energia Solar.

INMET. (2015). Boletim Agroclimatológico mensal de janeiro – 2015 (Instituto Nacional de Meteorologia (ed.)). Ministério da Agricultura, Pecuária e Abastecimento (MAPA).

INMET. (2020). BDMEP - Banco de Dados Meteorológicos para Ensino e Pesquisa. Instituto Nacional de Meteorologia; Instituto Nacional de Meteorologia. Available at: <http://www.inmet.gov.br/projetos/rede/pesquisa/>

Jahromi, M. S. B., Kalantar, V., Akhijahani, H. S., & Kargarsharifabad, H. (2022). Recent progress on solar cabinet dryers for agricultural products equipped with energy storage using phase change materials. Journal of Energy Storage, 51, 104434. https://doi.org/10.1016/j.est.2022.104434

Jangam, S. V., Law, C. L., & Mujumdar, A. S. (2010). Drying of foods, vegetables and fruits (1st ed.). National University of Singapore. 232 p.

Jideani, V.A., Mpotokwana, S. M. (2009). Modeling of water absorption of botswana bambara varieties using Peleg’s equation. Journal of Food Engineering, 92(1), 182-188.

Lamidi, R. O., Jiang, L., Pathare, P. B., Wang, Y. D., & Roskilly, A. P. (2019). Recent advances in sustainable drying of agricultural produce: A review. Applied Energy, 233–234, 367–385. https://doi.org/10.1016/j.apenergy.2018.10.044

Leite, A. L. M. P., Silva, F. S. da, Porto, A. G., Piasson, D., & Santos, P. dos. (2015). Contração volumétrica e cinética de secagem de fatias de banana variedade Terra. Pesquisa Agropecuária Tropical, 45(2), 155–162. https://doi.org/10.1590/1983-40632015v4530270

Lingayat, A., & Chandramohan, V. P. (2021). Numerical investigation on solar air collector and its practical application in the indirect solar dryer for banana chips drying with energy and exergy analysis. Thermal Science and Engineering Progress, 26, 101077. https://doi.org/10.1016/j.tsep.2021.101077

Lingayat, A., Chandramohan, V. P., & Raju, V. R. K. (2017). Design, Development and Performance of Indirect Type Solar Dryer for Banana Drying. Energy Procedia, 109, 409–416. https://doi.org/10.1016/j.egypro.2017.03.041

Lingayat, A., Chandramohan, V. P., & Raju, V. R. K. (2020). Energy and Exergy Analysis on Drying of Banana Using Indirect Type Natural Convection Solar Dryer. Heat Transfer Engineering, 41(6–7), 551–561. https://doi.org/10.1080/01457632.2018.1546804

Madamba, P. S., Driscoll, R. H., & Buckle, K. A. (1996). The thin-layer drying characteristics of garlic slices. Journal of Food Engineering, 29(1), 75–97. https://doi.org/10.1016/0260-8774(95)00062-3

Marulanda-Meza, S., & Burbano-Jaramillo, J. C. (2021). Evaluación energética de un deshidratador solar tipo túnel para frutas. Revista UIS ingenierías, 20(2), 31-44. https://doi.org/10.18273/revuin.v20n2-2021003

Mehran, S., Nikian, M., Ghazi, M., Zareiforoush, H., & Bagheri, I. (2019). Experimental investigation and energy analysis of a solar-assisted fluidized-bed dryer including solar water heater and solar-powered infrared lamp for paddy grains drying. Solar Energy, 190, 167–184. https://doi.org/10.1016/j.solener.2019.08.002

Meloni (2021). Desidratadores de alimentos. Available at: <https://www.melonidesi dratadores.com.br/>

Nasri, F. (2020). Solar thermal drying performance analysis of banana and peach in the region of Gafsa (Tunisia). Case Studies in Thermal Engineering, 22, 100771. https://doi.org/10.1016/j.csite.2020.100771

Oliveira, M. T. R., Berbert, P. A., & Martinazzo, A. P. (2013). Avaliação de modelos matemáticos na descrição das curvas de secagem por convecção de Pectis brevipedunculata (Gardner) Sch. Bip. Revista Brasileira de Plantas Medicinais, 15(1), 1–12. https://doi.org/10.1590/S1516-05722013000100001

Panchariya, P. C., Popovic, D., & Sharma, A. L. (2002). Thin-layer modelling of black tea drying process. Journal of Food Engineering, 52(4), 349–357.

Rodrigues, A. F., Silva, W. P., Gomes, J. P., Silva, C. M. D., & Ramos, Í. C. (2015). Estudo da secagem de bananas através do modelo de difusão usando soluções analíticas. In CONVIBRA – Agronomy Congress. Available at: <https://www.researchgate.net/publication/316841647>

Roratto, T. B., Monteiro, R. L., Carciofi, B. A. M., & Laurindo, J. B. (2021). An innovative hybrid-solar-vacuum dryer to produce high-quality dried fruits and vegetables. LWT, 140, 110777. https://doi.org/10.1016/j.lwt.2020.110777

Santos, S. G. F. dos, Miranda Netto, H. S., Cruz, D. R. C., Sarti, J. K., Rodovalho, R. S., & Almeida, V. G. (2021). Cinética de secagem e propriedades termodinâmicas de fatias de banana maçã tropical (Musa spp). Científica, 49(3), 113. https://doi.org/10.15361/1984-5529.2021v49n3p113-120

Silva, Á. G. F. da, Cruz, R. R. P., Moreira, W. G., Pereira, M. A. F., Silva, A. S., Costa, F. B. da, Nascimento, A. M. do, Souza, P. A. de, Timoteo, A. L. dos S., & Ribeiro, W. S. (2022). Solar drying of “Prata” bananas. Food Science and Technology, 42. https://doi.org/10.1590/fst.75021

Silva, A. S. A., dos Santos Melo, K., Alves, N. M. C., & Gomes, J. P. (2009). Cinética de secagem em camada fina da banana maçã em secador de leito fixo. Revista de Biologia e Ciências da Terra, 9(2), 107-115. http://dx.doi.org/10.15871/1517-8595/rbpa.v11n2p129-136

Silva, K., Neris, T., Loss, R., Silva, S., & Guedes, S. (2017). Caracterização da biomassa da banana-maçã (Musa spp.) em diferentes estádios de maturação in natura e desidratada. Enciclopédia Biosfera, 14(26), 131–143. https://doi.org/10.18677/encibio_2017b12

Silva, L. A., Arévalo, C. R. B., Pinedo, A. A., Maldonado, C. A. B., Cortez-Vega, W. R., Pizato, S., & Pinedo, R. A. (2021). Curvas de secagem e coeficiente de difusão de banana (Musa paradisíaca L.). Ciência e Tecnologia dos Alimentos, 11, 22-29. Editora Poisson. https://doi.org/10.36229/978-65-5866-097-2.CAP.05

Singh, D., & Mall, P. (2020). Experimental investigation of thermal performance of indirect mode solar dryer with phase change material for banana slices. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 1–18. https://doi.org/10.1080/15567036.2020.1810825

Sivakumar, S., Velmurugan, C., Dhas, D. E. J., Solomon, A. B., & Wins, K. L. D. (2020). Effect of nano cupric oxide coating on the forced convection performance of a mixed-mode flat plate solar dryer. Renewable Energy, 155, 1165-1172. https://doi.org/10.1016/j.renene.2020.04.027

TBCA. (2023). Brazilian Food Composition Table (TBCA). Tabela Brasileira de Composição de Alimentos - TBCA. http://www.fcf.usp.br/tbca

Tunckal, C., & Doymaz, İ. (2020). Performance analysis and mathematical modelling of banana slices in a heat pump drying system. Renewable Energy, 150, 918–923. https://doi.org/10.1016/j.renene.2020.01.040

United Nations (2022). The 17 goals. United Nations. Available at: <https://sdgs.un.org/goals>

Weather Spark. (2017). Condições meteorológicas médias de Barreiras, Brasil. Cedar Lake Ventures.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Rafael Fernandes Almeida, Patrícia de Magalhães Prado, Camila Filgueira de Souza, Vanessa Regina Kunz, Bruna Peregrino de Souza, Claudia Elizabeth da Silva Moraes, Elizangela Gonçalves de Oliveira

This work is licensed under a Creative Commons Attribution 4.0 International License.

This journal publishes its Open Access articles under a Creative Commons license (CC BY 4.0).

You are free to:

Share — copy and redistribute the material in any medium or format for any purpose, even commercially.

Adapt — remix, transform, and build upon the material for any purpose, even commercially.

The licensor cannot revoke these freedoms as long as you follow the license terms.

Under the following terms:

Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

No additional restrictions — You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits.

Notices:

You do not have to comply with the license for elements of the material in the public domain or where your use is permitted by an applicable exception or limitation.

No warranties are given. The license may not give you all of the permissions necessary for your intended use. For example, other rights such as publicity, privacy, or moral rights may limit how you use the material.

Funding data

-

Coordenação de Aperfeiçoamento de Pessoal de Nível Superior

Grant numbers 88887.847010/2023-00