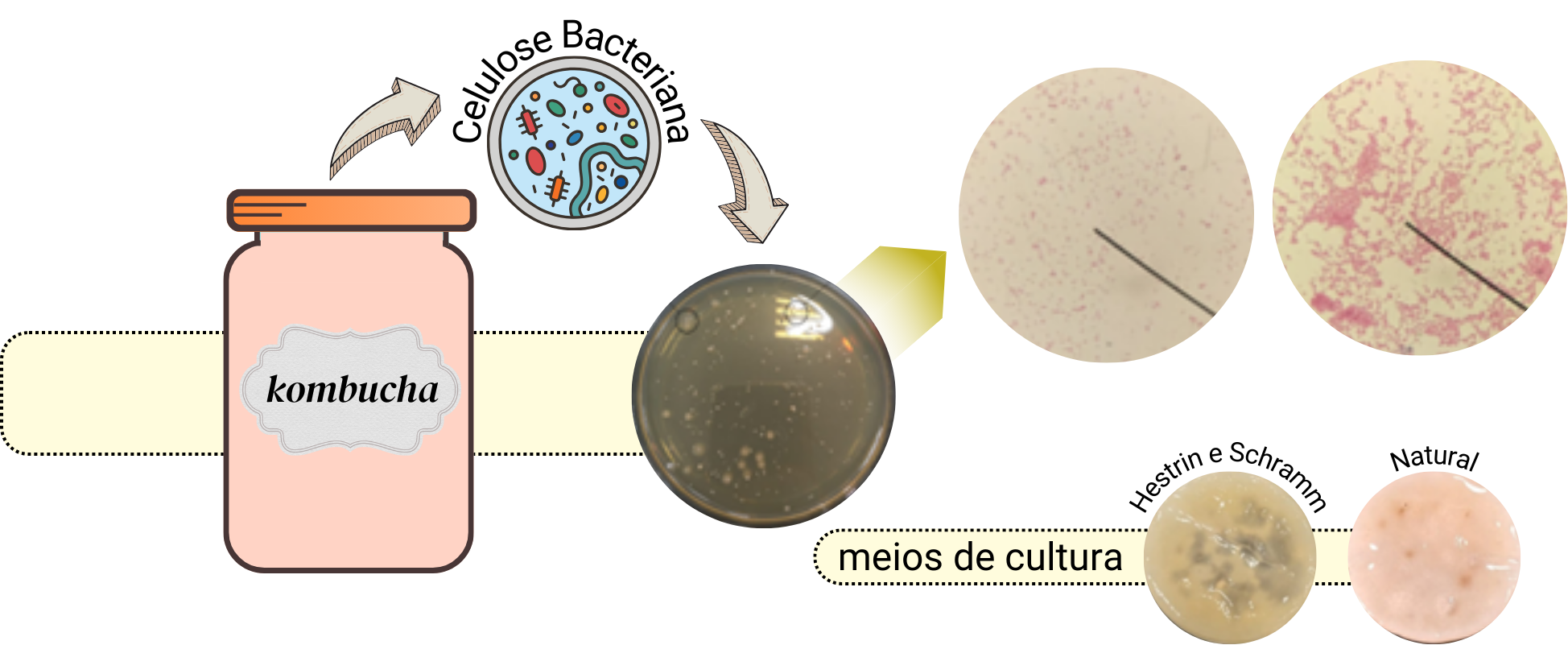

Production of bacterial cellulose (BC) in different media from kumbucha cultures

DOI:

https://doi.org/10.58951/fstoday.2024.004Keywords:

Bacterial cellulose, Bacterial cellulose production, Bacterial cellulose yield, kombucha, microorganism variabilityAbstract

Bacterial cellulose (BC) has elicited significant scientific interest due to its potential applications across various sectors, including medical, cosmetic, food, environmental, and fashion industries. This interest stems from its attributes as a biodegradable, biocompatible material with notable mechanical properties, sourced from renewable origins. Furthermore, its production process is straightforward, yielding solely organic and compostable waste. The production of BC necessitates microorganisms and a cultured medium. While the Gram-negative bacterium Komagataeibacter xylinus is recognized as particularly efficient for BC production in isolation, consortia of microorganisms such as those found in kombucha have demonstrated promising yields under suitable culture conditions. Hence, this study endeavors to ascertain the diversity of microorganisms present in kombucha samples and their respective BC productivity across varied culture media. Four kombucha samples (designated A, B, C, and D), along with two types of culture media, HS and natural (comprising tea and sugar), were subjected to experimentation. Microorganism enumeration revealed sample C as the most abundant, followed by A, D, and B, with the identification of three distinct colony varieties. Among these, two exhibited morphological traits akin to short Gram-negative bacilli, characteristic of K. xylinus, and Gram-positive bacilli, suggesting a yeast strain. BC production proved more efficient when utilizing the natural culture medium, particularly evident in sample C, possibly attributable to favorable physical and chemical parameters within this growth medium. Notably, the natural culture medium exhibited heightened efficacy in BC production with cultures derived from kombucha sample C.

References

AOAC - Association of Official Analytical Chemists. (2005). Official Methods of analysis of AOAC International. 18. ed. Washington: AOAC, 2005. (18th ed.). AOAC International.

Bianchet, R. T., Cubas, A. L. V., Machado, M. M., & Moecke, E. H. S. (2020). Applicability of bacterial cellulose in cosmetics – bibliometric review. Biotechnology Reports, 27(III), e00502. https://doi.org/10.1016/j.btre.2020.e00502 DOI: https://doi.org/10.1016/j.btre.2020.e00502

Brasil. (2013). Módulo 7: Detecção e identificação de micobactérias de importância médica. In Agência Nacional de Vigilância Sanitária (Ed.), Microbiologia Clínica para o Controle de Infecção Relacionada à Assistência à Saúde (pp. 19–43). ANVISA.

Brown, A. J. (1886). XLIII. - On an acetic ferment which forms cellulose. Journal of the Chemical Society, Transactions, 49(545), 432–439. https://doi.org/10.1039/CT8864900432 DOI: https://doi.org/10.1039/CT8864900432

Cazón, P., & Vázquez, M. (2021). Bacterial cellulose as a biodegradable food packaging material: A review. Food Hydrocolloids, 113, 106530. https://doi.org/10.1016/j.foodhyd.2020.106530 DOI: https://doi.org/10.1016/j.foodhyd.2020.106530

Domskiene, J., Sederaviciute, F., & Simonaityte, J. (2019). Kombucha bacterial cellulose for sustainable fashion. International Journal of Clothing Science and Technology, 31(5), 644–652. https://doi.org/10.1108/IJCST-02-2019-0010 DOI: https://doi.org/10.1108/IJCST-02-2019-0010

Duarte, É. B., Andrade, F. K., Lima, H. L. S., Nascimento, E. S. do, Carneiro, M. J. M., Borges, M. de F., Luz, E. P. C. G., Chagas, B. S. das, & Rosa, M. de F. (2019). Celulose bacteriana: propriedades, meios fermentativos e aplicações. Documentos (Embrapa Agroindústria Tropical), 186, 1–37. https://www.infoteca.cnptia.embrapa.br/infoteca/handle/doc/1109174

Fernandes, I. de A. A., Pedro, A. C., Ribeiro, V. R., Bortolini, D. G., Ozaki, M. S. C., Maciel, G. M., & Haminiuk, C. W. I. (2020). Bacterial cellulose: From production optimization to new applications. International Journal of Biological Macromolecules, 164, 2598–2611. https://doi.org/10.1016/j.ijbiomac.2020.07.255 DOI: https://doi.org/10.1016/j.ijbiomac.2020.07.255

Gomes, N. O., Carrilho, E., Machado, S. A. S., & Sgobbi, L. F. (2020). Bacterial cellulose-based electrochemical sensing platform: A smart material for miniaturized biosensors. Electrochimica Acta, 349. https://doi.org/10.1016/j.electacta.2020.136341 DOI: https://doi.org/10.1016/j.electacta.2020.136341

Hibbert, H., & Barsha, J. (1931). Studies on Reactions Relating To Carbohydrates and Polysaccharides: Xxxix. Structure of the Cellulose Synthesized By the Action of Acetobacter Xylinus on Glucose . Canadian Journal of Research, 5(5), 580–591. https://doi.org/10.1139/cjr31-096 DOI: https://doi.org/10.1139/cjr31-096

Lavasani, P. S., Motevaseli, E., Shirzad, M., & Modarressi, M. H. (2017). Isolation and identification of Komagataeibacter xylinus from Iranian traditional vinegars and molecular analyses. Iranian Journal of Microbiology, 9(6), 338–347.

Lee, Y. A. (2016). Case study of renewable bacteria cellulose fiber and biopolymer composites in sustainable design practices. Environmental Footprints and Eco-Design of Products and Processes, 141–162. https://doi.org/10.1007/978-981-10-0522-0_6 DOI: https://doi.org/10.1007/978-981-10-0522-0_6

Lin, D., Liu, Z., Shen, R., Chen, S., & Yang, X. (2020). Bacterial cellulose in food industry: Current research and future prospects. International Journal of Biological Macromolecules, 158, 1007–1019. https://doi.org/10.1016/j.ijbiomac.2020.04.230 DOI: https://doi.org/10.1016/j.ijbiomac.2020.04.230

Mohammadkazemi, F., Azin, M., & Ashori, A. (2015). Production of bacterial cellulose using different carbon sources and culture media. Carbohydrate Polymers, 117, 518–523. https://doi.org/10.1016/j.carbpol.2014.10.008 DOI: https://doi.org/10.1016/j.carbpol.2014.10.008

Ng, F. M. ., & Wang, P. W. (2016). Natural Self-grown Fashion From Bacterial Cellulose: A Paradigm Shift Design Approach In Fashion Creation. Design Journal, 19(6), 837–855. https://doi.org/10.1080/14606925.2016.1208388 DOI: https://doi.org/10.1080/14606925.2016.1208388

Nguyen, V. T., Gidley, M. J., & Dykes, G. A. (2008). Potential of a nisin-containing bacterial cellulose film to inhibit Listeria monocytogenes on processed meats. Food Microbiology, 25(3), 471–478. https://doi.org/10.1016/j.fm.2008.01.004 DOI: https://doi.org/10.1016/j.fm.2008.01.004

Núñez, D., Cáceres, R., Ide, W., Varaprasad, K., & Oyarzún, P. (2020). An ecofriendly nanocomposite of bacterial cellulose and hydroxyapatite efficiently removes lead from water. International Journal of Biological Macromolecules, 165, 2711–2720. https://doi.org/10.1016/j.ijbiomac.2020.10.055 DOI: https://doi.org/10.1016/j.ijbiomac.2020.10.055

Oprea, M., Panaitescu, D. M., Nicolae, C. A., Raluca, A., Frone, A. N., Raditoiu, V., Trusca, R., & Casarica, A. (2020). Nanocomposites from functionalized bacterial cellulose and poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polymer Degradation and Stability, 179. https://doi.org/10.1016/j.polymdegradstab.2020.109203 DOI: https://doi.org/10.1016/j.polymdegradstab.2020.109203

Pacheco, G., Nogueira, C. R., Meneguin, A. B., Trovatti, E., Silva, M. C. C., Machado, R. T. A., Ribeiro, S. J. L., da Silva Filho, E. C., & da S. Barud, H. (2017). Development and characterization of bacterial cellulose produced by cashew tree residues as alternative carbon source. Industrial Crops and Products, 107(May), 13–19. https://doi.org/10.1016/j.indcrop.2017.05.026 DOI: https://doi.org/10.1016/j.indcrop.2017.05.026

Picheth, G. F., Pirich, C. L., Sierakowski, M. R., Woehl, M. A., Sakakibara, C. N., de Souza, C. F., Martin, A. A., da Silva, R., & de Freitas, R. A. (2017). Bacterial cellulose in biomedical applications: A review. International Journal of Biological Macromolecules, 104, 97–106. https://doi.org/10.1016/j.ijbiomac.2017.05.171 DOI: https://doi.org/10.1016/j.ijbiomac.2017.05.171

Provin, A. P., dos Reis, V. O., Hilesheim, S. E., Bianchet, R. T., de Aguiar Dutra, A. R., & Cubas, A. L. V. (2021). Use of bacterial cellulose in the textile industry and the wettability challenge—a review. Cellulose, 28(13), 8255–8274. https://doi.org/10.1007/s10570-021-04059-3 DOI: https://doi.org/10.1007/s10570-021-04059-3

Sederavičiūtė, F., Bekampienė, P., & Domskienė, J. (2019). Effect of pretreatment procedure on properties of Kombucha fermented bacterial cellulose membrane. Polymer Testing, 78(February). https://doi.org/10.1016/j.polymertesting.2019.105941 DOI: https://doi.org/10.1016/j.polymertesting.2019.105941

Sriplai, N., & Pinitsoontorn, S. (2021). Bacterial cellulose-based magnetic nanocomposites: A review. Carbohydrate Polymers, 254, 117228. https://doi.org/10.1016/j.carbpol.2020.117228 DOI: https://doi.org/10.1016/j.carbpol.2020.117228

Stegemann, C., Almeida, A. d R., & Medeiros, H. de S. (2022). Biofabricação: um horizonte sustentável para o mundo da moda. Revista E-TECH: Tecnologias Para Competitividade Industrial - ISSN - 1983-1838, 15(2), 1–18. https://doi.org/10.18624/etech.v15i2.1214 DOI: https://doi.org/10.18624/etech.v15i2.1214

Sulaeva, I., Henniges, U., Rosenau, T., & Potthast, A. (2015). Bacterial cellulose as a material for wound treatment: Properties and modifications: A review. Biotechnology Advances, 33(8), 1547–1571. https://doi.org/10.1016/j.biotechadv.2015.07.009 DOI: https://doi.org/10.1016/j.biotechadv.2015.07.009

Szymańska, M., Hoppe, J., Dutkiewicz, M., Sobolewski, P., Palacz, M., Janus, E., Zielińska, B., & Drozd, R. (2022). Silicone polyether surfactant enhances bacterial cellulose synthesis and water holding capacity. International Journal of Biological Macromolecules, 208(March), 642–653. https://doi.org/10.1016/j.ijbiomac.2022.03.124 DOI: https://doi.org/10.1016/j.ijbiomac.2022.03.124

Tabaii, M. J., & Emtiazi, G. (2016). Comparison of bacterial cellulose production among different strains and fermented media. Applied Food Biotechnology, 3(1), 35–41. https://doi.org/10.22037/afb.v3i1.10582

Torres, F. G., Arroyo, J. J., & Troncoso, O. P. (2019). Bacterial cellulose nanocomposites: An all-nano type of material. Materials Science and Engineering: C, 98, 1277–1293. https://doi.org/10.1016/j.msec.2019.01.064 DOI: https://doi.org/10.1016/j.msec.2019.01.064

Ul-Islam, M., Khan, S., Ullah, M. W., & Park, J. K. (2019). Comparative study of plant and bacterial cellulose pellicles regenerated from dissolved states. International Journal of Biological Macromolecules, 137, 247–252. https://doi.org/10.1016/j.ijbiomac.2019.06.232 DOI: https://doi.org/10.1016/j.ijbiomac.2019.06.232

Volova, T. G., Shumilova, A. A., Nikolaeva, E. D., Kirichenko, A. K., & Shishatskaya, E. I. (2019). Biotechnological wound dressings based on bacterial cellulose and degradable copolymer P(3HB/4HB). International Journal of Biological Macromolecules, 131, 230–240. https://doi.org/10.1016/j.ijbiomac.2019.03.068 DOI: https://doi.org/10.1016/j.ijbiomac.2019.03.068

Wahid, F., Zhao, X. Q., Cui, J. X., Wang, Y. Y., Wang, F. P., Jia, S. R., & Zhong, C. (2022). Fabrication of bacterial cellulose with TiO2-ZnO nanocomposites as a multifunctional membrane for water remediation. Journal of Colloid and Interface Science, 620, 1–13. https://doi.org/10.1016/j.jcis.2022.03.108 DOI: https://doi.org/10.1016/j.jcis.2022.03.108

Wang, J., Sun, B., Cao, Y., Tian, Y., & Li, X. (2008). Optimisation of ultrasound-assisted extraction of phenolic compounds from wheat bran. Food Chemistry, 106(2), 804–810. https://doi.org/10.1016/j.foodchem.2007.06.062 DOI: https://doi.org/10.1016/j.foodchem.2007.06.062

Wang, J., Tavakoli, J., & Tang, Y. (2019). Bacterial cellulose production, properties and applications with different culture methods – A review. Carbohydrate Polymers, 219(May), 63–76. https://doi.org/10.1016/j.carbpol.2019.05.008 DOI: https://doi.org/10.1016/j.carbpol.2019.05.008

Wood, J. (2019). Bioinspiration in Fashion-A Review. Biomimetics, 4(1). https://doi.org/10.3390/biomimetics4010016 DOI: https://doi.org/10.3390/biomimetics4010016

Yim, S. M., Song, J. E., & Kim, H. R. (2017). Production and characterization of bacterial cellulose fabrics by nitrogen sources of tea and carbon sources of sugar. Process Biochemistry, 59, 26–36. https://doi.org/10.1016/j.procbio.2016.07.001 DOI: https://doi.org/10.1016/j.procbio.2016.07.001

Zeng, X., Small, D. P., & Wan, W. (2011). Statistical optimization of culture conditions for bacterial cellulose production by Acetobacter xylinum BPR 2001 from maple syrup. Carbohydrate Polymers, 85(3), 506–513. https://doi.org/10.1016/j.carbpol.2011.02.034 DOI: https://doi.org/10.1016/j.carbpol.2011.02.034

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Aline da Rosa Almeida, Cristiane Stegemann, Matheus Vinicius Oliveira Brisola Maciel, Ayme de Braga da Costa, Thaís Regina Coelho Schadeck, Henrique de Souza Medeiros, Morgana Stegemann, Rafael Dutra de Armas

This work is licensed under a Creative Commons Attribution 4.0 International License.

This journal publishes its Open Access articles under a Creative Commons license (CC BY 4.0).

You are free to:

Share — copy and redistribute the material in any medium or format for any purpose, even commercially.

Adapt — remix, transform, and build upon the material for any purpose, even commercially.

The licensor cannot revoke these freedoms as long as you follow the license terms.

Under the following terms:

Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

No additional restrictions — You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits.

Notices:

You do not have to comply with the license for elements of the material in the public domain or where your use is permitted by an applicable exception or limitation.

No warranties are given. The license may not give you all of the permissions necessary for your intended use. For example, other rights such as publicity, privacy, or moral rights may limit how you use the material.

Funding data

-

Conselho Nacional de Desenvolvimento Científico e Tecnológico

Grant numbers 350722/2022-6 -

Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina

Grant numbers 2022TR001116